You have no items to compare.

Search results for '912-914 INTAKE MANIFOLD'

-

$4.85Great for 912/914 922-250 and 922-192 engine 17mm ID coolant hoses.

-

-

$17.5012 mm Replacement Adapter for 912 Differental Pressure Tester

-

$803.02See Description for Important Information

-

$197.652-1/4" Square Tachometer with Hour Meter Drive

-

$499.402-Stroke Standard EIS (does not include probes/senders)

-

$25.16200 MM Water Hose DIN 73411-17x4-B-EPDM

-

$35.60285 MM Water Hose DIN 73411-17x4-B-EPDM

-

-

Starting at: $1.59

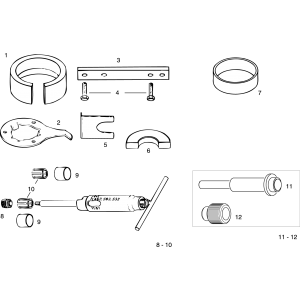

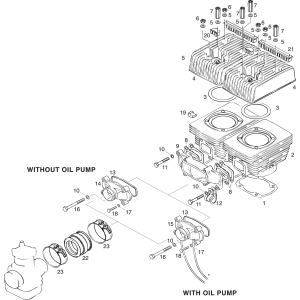

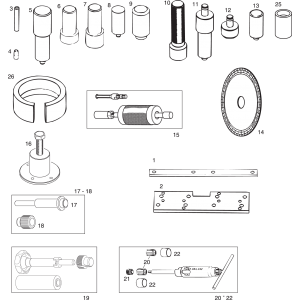

a – For installation of cylinder on the piston 67.5 mm;

b – For installation of cylinder on the piston 72 mm;

c – To hold the fan;

d – For aligning of cylinders at the intake flange;

e – For crankshaft bearing PTO side;

f – For positioning of crankshaft bearing PTO side;

g – For centering of the stator plate;

h – For piston pin 18 mm;

i – For installation of piston pin circlip 18 mm;

j – For the engine;

k – Without ignition and externals -

Starting at: $0.12

a – RED 67.50 MM - 67.51 MM, GREEN 67.51 - 67.52 MM;

b – Cylinder PTO side;

c – Cylinder MAG side -

Starting at: $0.17

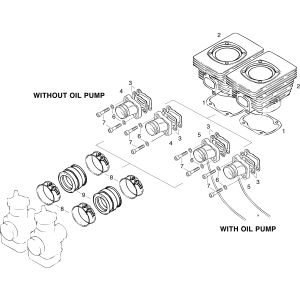

b – For mixture lubrication;

c – For oil pump version -

Starting at: $0.12

b – For mixture lubrication;

c – For oil pump version -

Starting at: $5.52

a – For cylinder;

b – For cylinder exhaust flange;

c – For rotary valve shaft;

d – For ball bearing, rotary valve shaft;

e – For oil seal rotary valve shaft (wihout oil pump), intake side;

f – For oil seal rotary valve shaft (with oil pump), intake side;

g – For inner oil seal rotary valve shaft, water pump side;

h – For outer oil seal rotary valve shaft, water pump side;

i – To press in the rotary seal;

j – For rotary valve timing;

k – To pull out the rotary seal - the inner steel bushing of the rotary seal has to be removed before demounting!;

l – For fitting of piston pin circlip;

m – For fitting of piston pin circlip (monohook circlip);

q – To press in the rotary seal 850942 with the insertion jig -

Starting at: $0.17

A – Loctite 221

a – For configuration without oil pump

-

$11.1685 MM Water Hose DIN 73411-17x4-B-EPDM

-

-

-

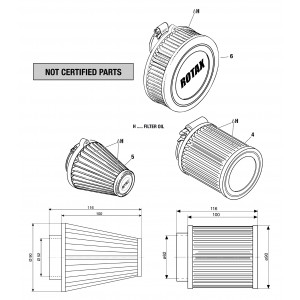

Starting at: $0.00

H – Oil filter

d – See Service Instruction SI-912-017 current issue

-

Starting at: $1.58

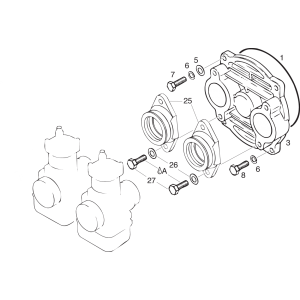

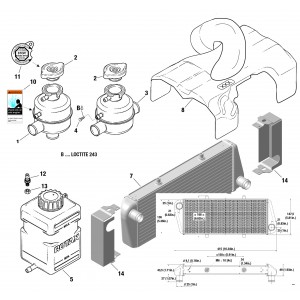

B – Loctite 243

AR – As required

a – Short version, marked with S/N;

b – Edition Diamond, marked with S/N;

c – See Service Instruction SI-912-020 / SI-914-022 current issue;

d – See Service Bulletin SB-912-039 / SB-914-029 current issue; e – See Service Bulletin SB-912-043 / SB-914-029 current issue;

f – Same outline dimensions and brackets as TNr. 995698, but with improved cooling performance (18% bigger cooling surface);

g – Use together with P/N 997083, for retrofit instead of radiator P/N 997082 -

Starting at: $0.12

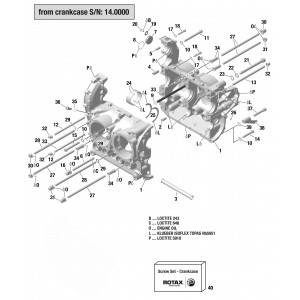

B – Loctite 243

C – Loctite 648

L – Klueber Isoflex Topas Nb5051

O – Engine Oil

P – Loctite 5910a – Only for model 2 and 4;

b – Tolerance group "C" 1.820 - 1.829 mm;

c – Tolerance group "C" 1.830 - 1.839 mm;

d – See Overhaul Manual of the respective engine type, current issue -

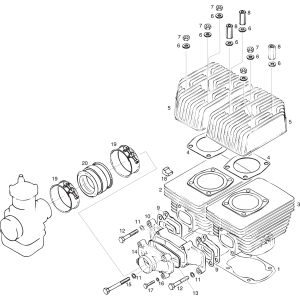

Starting at: $0.12

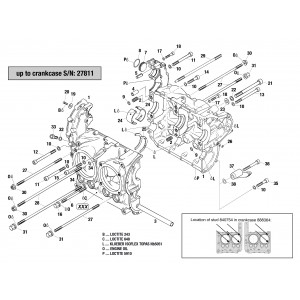

B – Loctite 243

C – Loctite 648

L – Klueber Isoflex Topas Nb5051

O – Engine Oil

P – Loctite 5910a – marked with S/N;

b – Only for model 2 and 4;

c – Tolerance group "C" 1.820 - 1.829 mm;

d – Tolerance group "D" 1.830 - 1.839 mm;

e – Depending on configuration use 14 studs P/N 840752 M8x201 or 8 studs M8x201 and 6 studs P/N 840754 m8x210;

f – See Overhaul Manual of the respective engine type, current issue;

g – Only for use with new cylinders 913221 with countersunk. With the cylinder 913225 the countersunk was already introduced starting from beginnng of the production;

h – See the following Service Instruction current issue SI-914-021;

i – Without O-Ring from S/N 06.0010 to 07.5000, 2x O-Ring starting with S/N 07.5001;

j – 431570 introduced as per engine S/N as follows: 912 UL S/N 06,770.893, 912 ULS S/N 06,781.191, 914 UL S/N 07,682.596;

k – Wrench size A/F 11 -

Starting at: $0.12

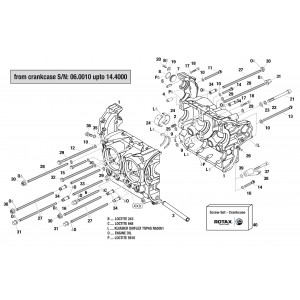

B – Loctite 243

C – Loctite 648

L – Klueber Isoflex Topas Nb5051

O – Engine Oil

P – Loctite 5910a – marked with S/N;

b – Only for model 2 and 4;

c – Tolerance group "C" 1.820 - 1.829 mm;

d – Tolerance group "D" 1.830 - 1.839 mm;

e – Depending on configuration use 14 studs P/N 840752 M8x201 or 8 studs M8x201 and 6 studs P/N 840754 m8x210;

f – See Overhaul Manual of the respective engine type, current issue;

g – Only for use with new cylinders 913221 with countersunk. With the cylinder 913225 the countersunk was already introduced starting from beginning of the production;

h – See the following Service Instruction current issue SI-914-021. -

Starting at: $0.00

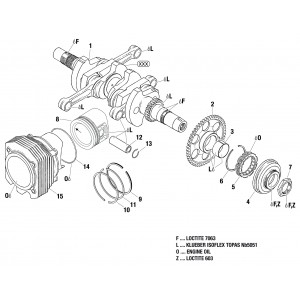

F – Loctite 7063

L – Klueber Isoflex Topas Nb5051

O – Engine Oil

Z – Loctite 603e – At 912 ULS the complete piston with rings has to be exchanged up to S/N 4,425.123;

f – With countersunk for O-ring 830415. 912 UL: 4,403.679, 912 ULS: Starting with serial production, 914 UL: 4,417.868;

g – Note following Service Letter: SL-912-002 current issue, SL-914-002 current issue,

h – With expanded space of sprag clutch. Introduced as per following engine S/N 912 UL: 4,409.089, 912 ULS: 5,650.835, 914 UL: 6,772.727;

i - Balanced pistons set: max. difference 3 g -

Starting at: $0.00

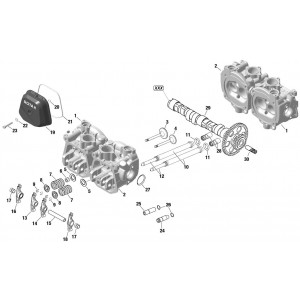

C – Loctite 638

L – Klueber Isoflex Topas Nb5051

O – Engine OilAR – As required

a – For cylinder 2 and 3;

b – For cylinder 1 and 4;

c – Up to engine S/N 912 UL: 4,401.879, 914 UL: 4,417.597, single valve springs and double valve springs if required are allowed to be mounted in one engine;

d – From engine S/N 912 UL: 4,401.880, 914 UL: 4,417.598;

e – With sintered bronze bushing;

f – Oversize +0.2 mm (0.008 in.);

g – Rocker arm version with vespel bushing, from engine S/N 912 UL: 4,404.621, 912 ULS: 4,427.487, 914 UL: 4,418.104;

h – For inlet valve, chafe up to new measurement;

i – For outlet valve, chafe up to new measurement;

j – Use only once!;

k – For rework of exhaust port. See Overhaul Manual of the respective engine type, current issue;

l – Marked with S/N;

m – Without worm gear;

n – Prefilled, 8 parts per set;

o – Cylinder heads where the coolant temperature is measured.

p – see SI-914-30

Loading, please wait...

Loading, please wait...